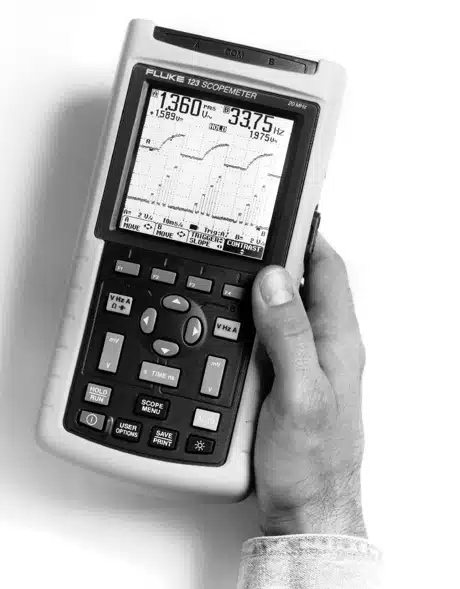

Fluke - 123 - ScopeMeter

Manufacturer:

Image 1 of 1

If you have any other photos or manuals for the

Fluke 123

you can

upload the files here.

Equipment:

123

Date:

1997

Category:

Group:

Sub Group:

Information

Dual input oscilloscope

Vertical

Frequency response

DC coupled:

Excluding probes and test leads:

DC to 20 MHz (-3 dB)

With STL120 1:1 shielded test leads:

DC to 12.5 MHz (-3 dB)

DC to 20 MHz (-6 dB)

With PM 8918 10:1 probe (optional

accessory): DC to 20 MHz (-3 dB)

AC coupled (LF roll off)

Excluding probes and test leads:

<10 Hz (-3 dB)

With STL120: <10 Hz (-3 dB)

With PM 8918: <1 Hz (-3 dB)

Rise time

Excluding probes and test leads:

<17.5 ns

Input impedance

Excluding probes and test leads:

1 MW//12 pF

With BB120: 1 MW//20 pF

With STL120: 1 MW//225 pF

With PM 8918: 10 MW//15 pF

Sensitivity: 5 mV to 500V/div

Display modes: A, -A, B, -B

Max input voltage

A, B: 600V rms up to 200 kHz,

derating to 6V rms @ 20 MHz

Max floating voltage

From any terminal to ground:

600V rms up to 400 Hz

Resolution: 8 bit

Vertical accuracy: ±(1% of reading

+ 0.05 range/div)

Max vertical move: ±4 divisions

Horizontal

Acquisition modes

Normal: Equivalent sampling: 20 ns

to 500 ns/div; real time sampling:

1 ms to 5s/div

Single (real time): 1 ms to 5s/div

Roll (real time): 1s to 60s/div

Sampling rate (for both channels

simultaneously): For repetitive

signals (equivalent sampling) up to

1.25 GS/s; real time (normal and

single): 1 ms to 5 ms/div, 25 MS/s;

10 ms to 5s/div, 5 MS/s

Time base accuracy

Equivalent sampling: ±(0.4%

of reading +0.04 time/div)

Real time sampling: ±(0.1%

of reading +0.04 time/div)

Glitch detection: ³40 ns

@ 20 ns to 5 ms/div; ³200 ns

@ 10 ms to 5s/div

Glitch detection is always active

Horizontal move, 10 divisions.

Permits shifting of the display

from 0 to 10 division of pre-trigger.

Trigger point will always be visible.

7 Manuals

Service manual

Manual type:

Service manual

Pages:

170

Size:

5.3 MB

Language:

english

Revision:

3

Manual-ID:

4822 872 05375

Date:

Quality:

Electronic document, no scan, very well readable.

Upload date:

Nov. 29, 2014

MD5:

d1e4ef72-a9bc-1d3f-a26a-274826207797

Downloads:

804

Service manual

Manual type:

Service manual

Pages:

96

Size:

2.0 MB

Language:

english

Revision:

Manual-ID:

4822 872 05398

Date:

Quality:

Electronic document, no scan, very well readable.

Upload date:

Nov. 29, 2014

MD5:

c87ad484-e83e-45f4-a080-37ec9a5bb2fb

Downloads:

1607

Datasheet

Manual type:

Datasheet

Pages:

4

Size:

729.8 KB

Language:

english

Revision:

A

Manual-ID:

J0661

Date:

Quality:

Electronic document, no scan, very well readable.

Upload date:

Nov. 30, 2014

MD5:

7d2cac54-6276-9204-8572-f02481b27222

Downloads:

602

User manual

Manual type:

User manual

Pages:

83

Size:

1.8 MB

Language:

english

Revision:

Manual-ID:

Date:

Quality:

Electronic document, no scan, very well readable.

Upload date:

Jan. 26, 2016

MD5:

06bfdf87-5407-2d73-3a7d-08576f198abd

Downloads:

915

Service manual

Manual type:

Service manual

Pages:

77

Size:

1.6 MB

Language:

english

Revision:

4

Manual-ID:

4822 872 00743

Date:

Quality:

Electronic document, no scan, very well readable.

Upload date:

Jan. 26, 2016

MD5:

39798c0a-3135-4b15-04be-d94ce32f6d3c

Downloads:

547

Service manual

Manual type:

Service manual

Pages:

174

Size:

7.1 MB

Language:

english

Revision:

Manual-ID:

4822 872 05389

Date:

February 2003

Quality:

Scanned document, all readable.

Upload date:

July 22, 2020

MD5:

798e0507-5681-c736-483f-f7a88df7f5da

Downloads:

373

User manual

Manual type:

User manual

Pages:

98

Size:

119.0 KB

Language:

english

Revision:

Manual-ID:

Date:

Quality:

Electronic document, no scan, very well readable.

Upload date:

March 20, 2023

MD5:

a339c682-aa67-a35f-8c3b-6ea3874aa0a7

Downloads:

0