Electro Scientific Industries - 253 - Level Meter

Manufacturer:

Image 1 of 1

If you have any other photos or manuals for the

Electro Scientific Industries 253

you can

upload the files here.

Equipment:

253

Date:

1979

Category:

Group:

Sub Group:

Information

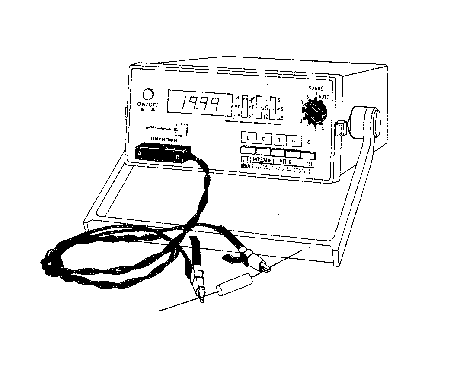

The ESI Model 253 Digital Impedance Meter is a

semi-automatic instrument which permits rapid measurement of

inductance (L) , capacitance (C) , resistance (R) ,

conductance (G) , and dissipation factor (D) at a test

frequency of 1kHz. Measurement accuracy and versatility

satisfies most demanding engineering or scientific

applications .

This instrument has both an autoranging mode and a manual

range selection mode. The autoranging feature eliminates the

need for manual range selecting, thus saving time and

avoiding operator errors. It is designed to measure an

unknown and select the lowest corresponding range

automatically, thereby providing the highest resolution

display. When a series of measurements are to be made within

a particular range, time can be saved by turning the range

switch to the corresponding fixed range position. Front

panel LED lamps indicate the unit of measurement being

displayed by the 3-1/2 digit LED readout.

To operate, merely push the button for the desired function,

manually turn the knob to the desired range, and connect the

unknown. KELVIN KLIPS® test leads are included, thus

ensuring true four-terminal connections.

Excellent reliability of the Model 253 is assured through

use of solid state devices and etched circuit board

construction. Its small size is ideal for use on benchtops

where work space may be at a premium. The carrying handle

tilts the unit to a convenient viewing angle. Rear panel

brackets provide line cord storage and enable it to be

operated in a vertical position.

1 Manual

Service and user manual

Manual type:

Service and user manual

Pages:

78

Size:

2.1 MB

Language:

english

Revision:

Manual-ID:

43761B

Date:

June 1985

Quality:

Scanned document, reading partly badly, partly not readable.

Upload date:

Sept. 12, 2016

MD5:

c47cb799-81b7-8741-fce7-06230dddc50a

Downloads:

530